Meat Processing

Kortlever have grown in the meat industry and are proving that their robust and hygienic equipment is suited to the manufacturing processes. They have a range of standard equipment but are most specialised in bespoke design and bespoke lines for the management of a meat processing factory's logistics. Take a look at a small selection of our equipment below and call us to enquire about your application

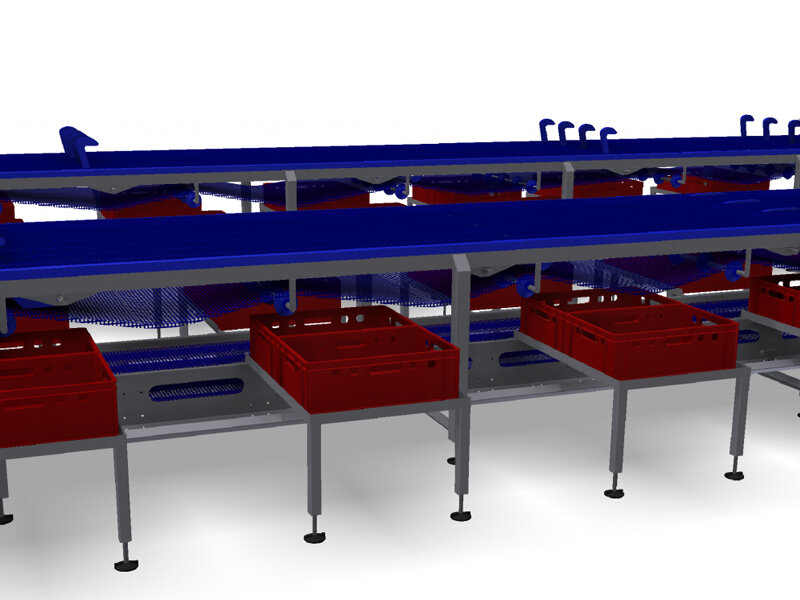

Cutting and Deboning

Kortlever designs and manufactures customized deboning solutions for dividing of pork and beef carcasses.

Our ergonomic layouts comply with applicable health and safety regulations.

The same procedure can be applied on beef deboning as well.

After dividing, the technical parts are automatically carried with various deboning belts to workstations for further processing and transport.

The pork carcasses are automatically supplied from the cooling area, put on a deboning conveyor and, afterwards, are divided in leg, loin/belly and shoulder by means of a laser controlled cutter.

Further Processing

Kortlever use the folding method typically, to produce high quality Chicken Cordon Bleu

The ‘Slavink’ unique to the Netherlands, which is minced meat wrapped in bacon, is made on the automated BWS lines from Kortlever

The sandwich method, using Kortlever’s high speed servo retracting conveyors will typically be used for Chicken Kiev

‘pigs in blankets’, cheese wrapped with salami or cheese wrapped in ham can also be made with the Kortlever BWS line

Projects and Solutions

Cutting Line Projects

Meat Feeding Systems

Cutting Room Solutions

Packing Systems